PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

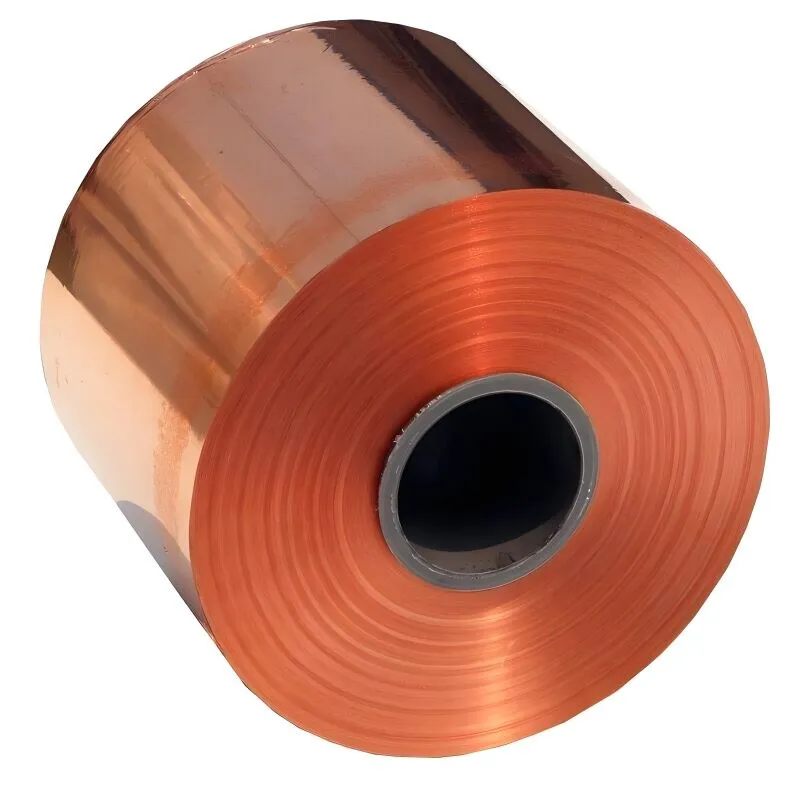

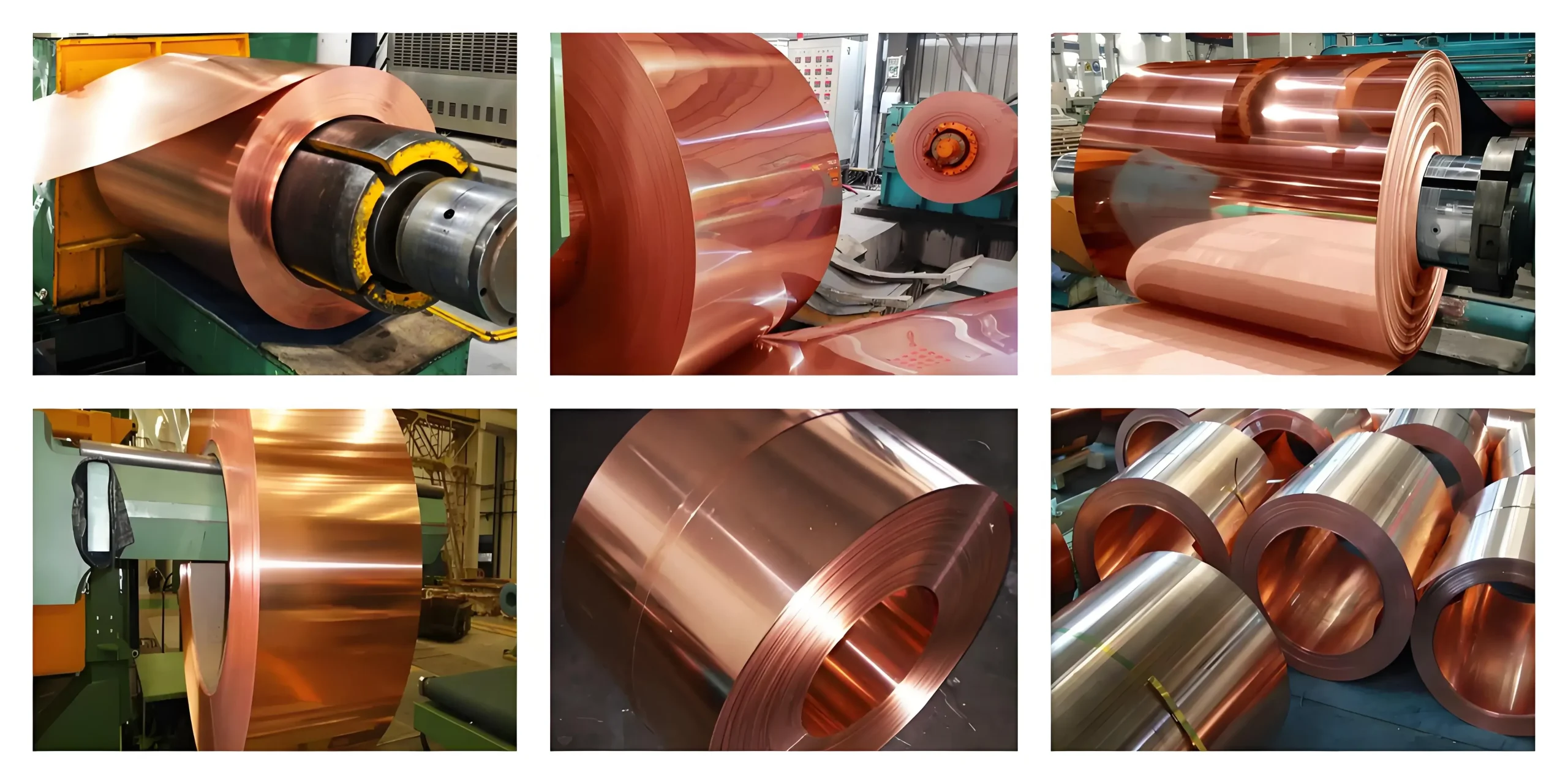

Copper coil

A copper coil is a component made of copper wire wound in a specific pattern. It is known for its excellent electrical conductivity and thermal conductivity. Copper coils are widely used in various applications such as in electrical equipment like transformers and inductors for energy transfer and storage. They are also employed in heating and cooling systems for efficient heat exchange. The malleability and ductility of copper allow for easy shaping and manipulation of the coils to meet specific design requirements.

![]() Whatsapp : +8615315787225

Whatsapp : +8615315787225

![]() Email : [email protected]

Email : [email protected]

application:

1. Electrical Engineering

– It is commonly used in transformers and inductors for power transmission and distribution. – Found in electrical motors and generators to create magnetic fields.

2. Refrigeration and Air Conditioning

– Utilized in heat exchangers to transfer heat and cool the system.

3. Plumbing

– Employed in water heating systems for efficient heat conduction.

4. Electronics

– As components in electronic circuits, such as coils for radio frequency applications.

5. Industrial Machinery

– Used in various machines for conducting electricity and controlling electrical signals.

6. Telecommunications

– Part of antenna systems and signal transmission equipment.

Product Description

| GB | ISO | ASTM | JIS | ||

|---|---|---|---|---|---|

| TU1 | Cu-OF | C10200 | C1020 | ||

| T2 | Cu-RTP | C11000 | C1100 | ||

| TP1 | Cu-DLP | C12000 | C1201 | ||

| TP2 | Cu-DHP | C12200 | C1220 | ||

| GB | Composition(%) | ||||

| Cu | P | O | Other | ||

| TU1 | 99.97 | 0.002 | less than 0.002 | balance | |

| T2 | 99.9 | – | – | balance | |

| TP1 | 99.9 | 0.004-0.012 | – | balance | |

| TP2 | 99.9 | 0.015-0.040 | – | balance | |

| ASTM | Composition(%) | ||||

| Cu | P | O | Other | ||

| C10200 | 99.95 | 0.001-0.005 | – | balance | |

| C11000 | 99.9 | – | – | balance | |

| C12000 | 99.9 | 0.004-0.012 | – | balance | |

| C12200 | 99.9 | 0.015-0.040 | – | balance | |

| Item | Copper Coil / Copper Strip / Copper Tape | ||||

| Standard | JIS H3100-2006 ,ASTM B152M-06,GB/T 2040-2008,ROCT 495-92,EN 1652-98,ASTM B171M-04, | ||||

| Material | C12300,C1020P,C10100,C10400,C10700,C10200,T2,C1100P,C10500,M1, | ||||

| Cu-ETP,TP1,C1201P,C11000,Cu-DLP,TP2,C1220P,C1221P,C1200,C12200, | |||||

| C14200,C23000P,H62,C2801P,C36500 | |||||

| Thickness | 0.01mm~20mm | ||||

| Width | 1mm~2500mm | ||||

| Length | Random size and customize or as required | ||||

| Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required | ||||

| Package | Standard export seaworthy or as customers’ requirements | ||||

| Application | Copper coil can be made to do all sorts of deep drawing and bending stress components,such as manufacturing pins,rivets,gasket,nuts,conduits,the barometer spring,screen,radiator parts, etc | ||||

| Come and contact us. | |||||

The physical and chemical properties of copper coil are as follows:

Physical Properties:

1. Electrical Conductivity: Copper is an excellent conductor of electricity. Copper coils have low electrical resistance, allowing for efficient transmission of electrical current.

2. Thermal Conductivity: It has high thermal conductivity, enabling effective heat transfer.

3. Ductility and Malleability: Copper is highly ductile and malleable, allowing the coil to be easily shaped and formed without breaking.

4. Density: Copper has a relatively high density.

Chemical Properties:

1. Corrosion Resistance: In dry and normal conditions, copper is relatively resistant to corrosion. However, in the presence of moisture and certain chemicals, it can oxidize and corrode over time.

2. Reactivity: Copper can react with some acids and oxidizing agents.

3. Oxidation: When exposed to air, copper slowly oxidizes, forming a layer of copper oxide on the surface. These physical and chemical properties make copper coil suitable for various applications in different fields.

Taiang steel

Product advantage

Taiang steel

Company Advanced

Powerful

It has been selected as one of the top 500 Chinese enterprises for 14 consecutive years, with strong financial and technical strength.

Advanced technology

Process efficiencyDRP information is fully integrated and controlled, and the steel production process is at a high level.

Perfect industrial layout

A steel enterprise that takes steel production as its leading industry and integrates commercial, high-tech and other industries.

R & D capability

Created a number of "firsts" in China's steel industry, with strong R & D capabilities and technological innovation capabilities

Wide range of products

The products cover products, varieties, and specifications, and can meet the diverse needs of customers in different fields.

Strong competitiveness

Products with high quality quickly occupied the domestic market and were successfully exported to many countries and regions.

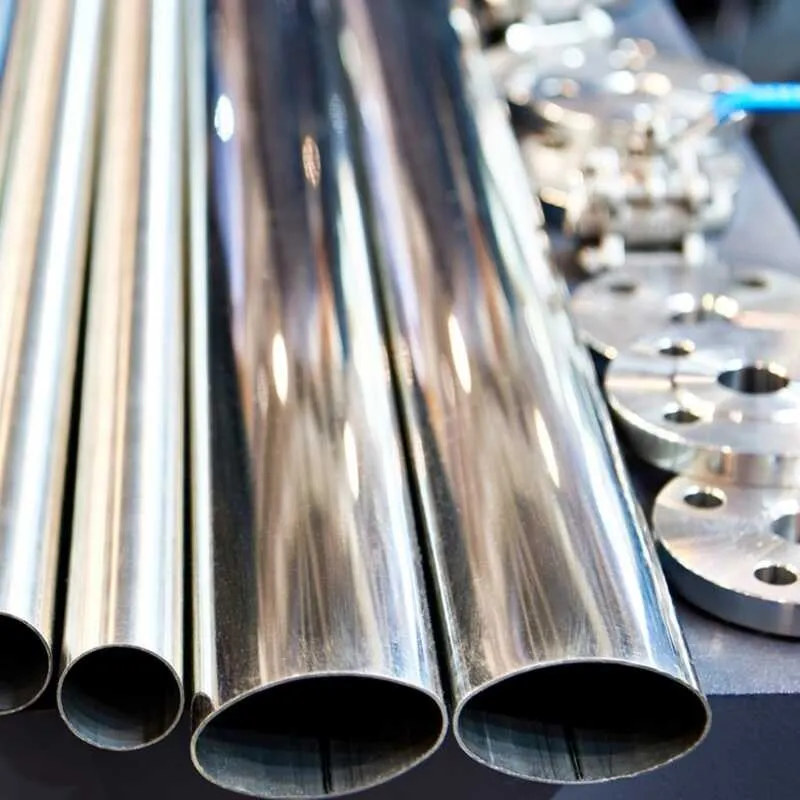

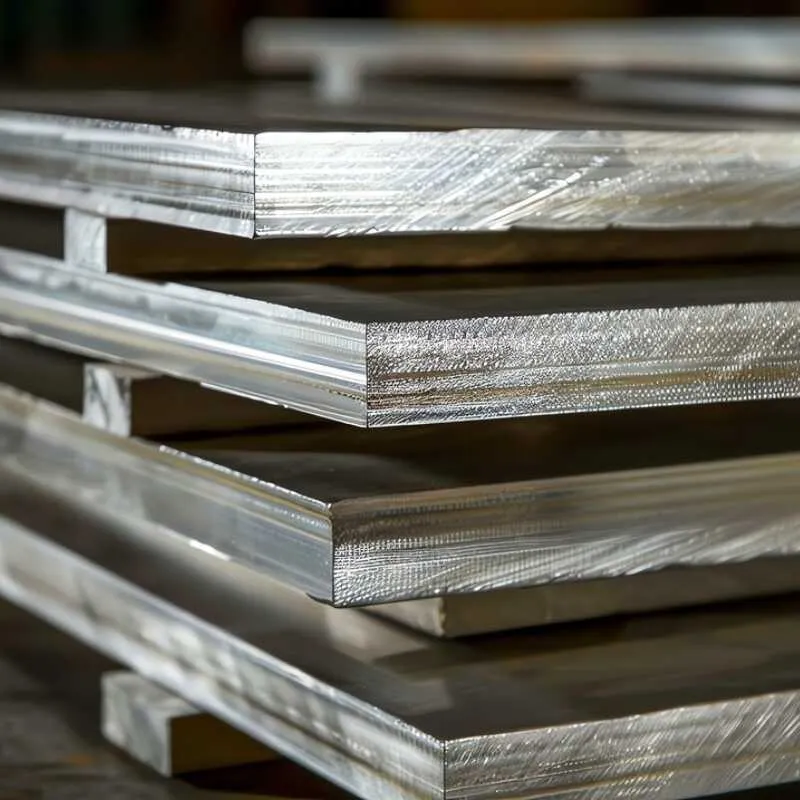

Related products

FAQ

A What range of steel products does your factory produce?

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

B Are your steel products certified or graded, and how can I trust their quality?

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

CCan your factory handle bulk orders within short time frames?

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

D How does your company ensure the sustainability of production?

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

E What measures are in place to ensure the safety and welfare of workers in your factory?

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

F Do you offer customized steel solutions for specific industry needs?

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

G How do you handle logistics and transportation, and can customers track their orders?

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

H What is your policy on returns or defective products?

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.

- We are professional and responsibal